Lightspeed Equipment’s screen printing exposure units are fast! Now we can say that Lightspeed Equipment is not only fast in the shop, but on the track as well!

We are one of the proud spons0rs of the Mueller Lightspeed Sprint Car, and are excited to end the season with the championship!

Driver Mike Mueller of Stacy, MN has won the 2017 UMSS Traditional Sprint Car Series point championship driving the Lightspeed Equipment Sprint Car.

Mike is a fantastic driver, and this is a great milestone is his career. To learn more about Mike and the series, checkout this article from Sprint Source: http://www.sprintsource.com/news/?i=53565

To learn more about Lightspeed Equipments championship screen printing exposure units and how they can save your business time & money while avoiding downtime, give us a call! We’d love to demo our patented multispectrum LED exposure technology and how it can improve the bottom line of your printing business FAST!

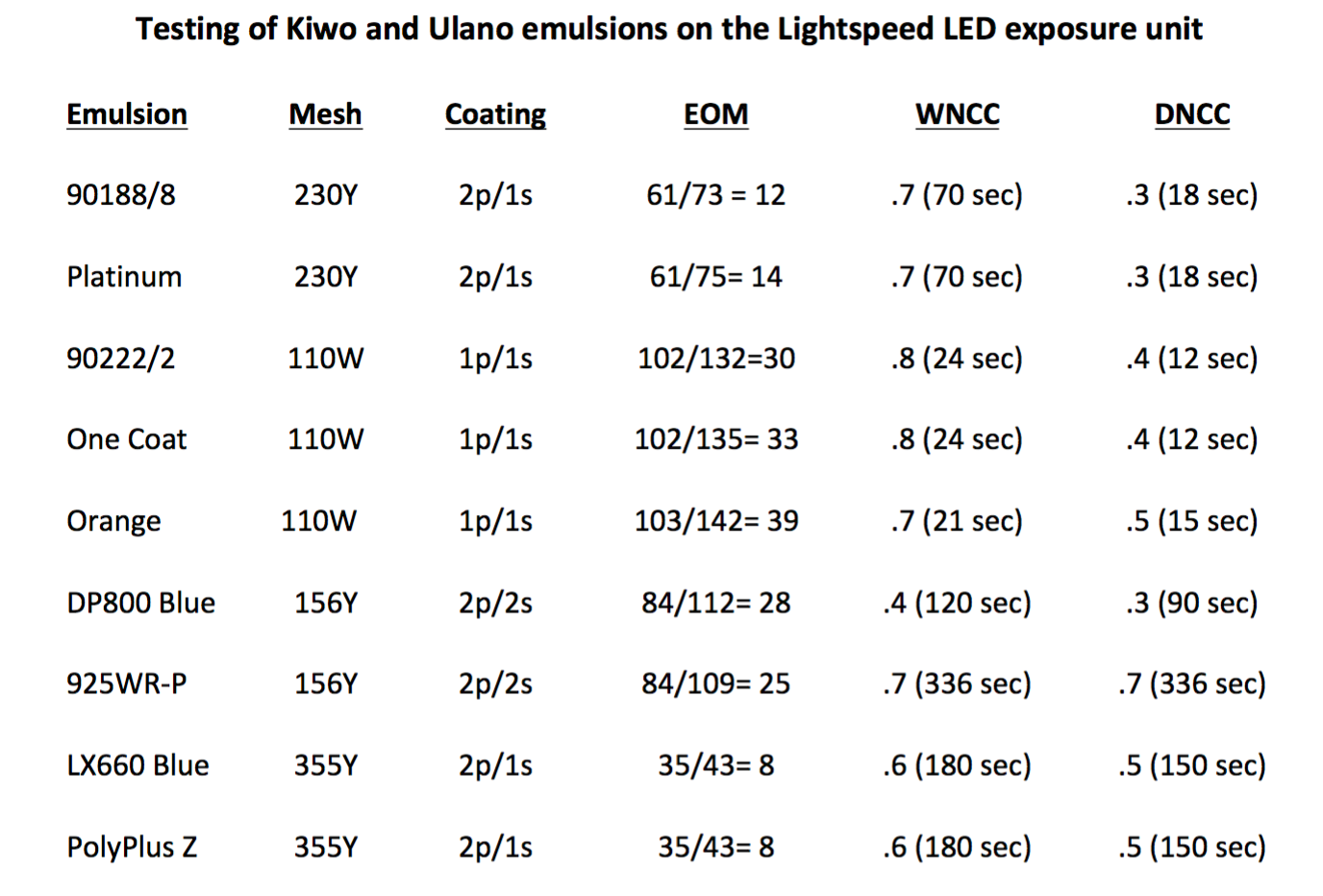

As you can see from the test results that Ulano shared with us, Lightspeed Equipment LED Screen Printing Exposure Unit is what they consider to be the best LED exposure unit tested to date!

“Overall, the results of this LED screen printing exposure unit with our emulsions was very good. Based on previous LED exposure unit testings, the Photopolymers were just a little slower, but not so much that it makes any difference.

All three Photopolymers had good edge and resolution. Orange and One Coat slightly better than 90222/2.

Platinum and 90188/8 were equal match for exposure. 90188/8 having better edge and resolution than Platinum, yet Platinum very good and very acceptable for textile printing. I treated both emulsions with On Press and let sit overnight. Platinum reclaimed very easy, 90188/8 needed pressure washer, but would still be considered easy to reclaim.

LX660 Blue and Poly Plus Z were the big surprise for me. The exposure speed was ok, but the edge definition and resolution was fantastic. You would be hard pressed to tell the difference from the LED screen and a 5K MH screen. Nothing like we have seen from all the other LED units where dots have conglomerations that make them look horrible. These were a pleasent surprise..

DP800 Blue exposed faster than the diazo dual cures, but did not have the same edge and resolution that they have. They were good, but not the same as LX660 or PPZ.. Dots were also slightly elongated.

925WR-P was slow, as expected. Good edge and resolution, but not as good as with a 5k MH.. Also had the elongated dots.

My opinion: I would not recommend the Lightspeed LED screen printing exposure unit for straight diazo emulsions, mostly because the speed is slow and the end result is not better than a MH. Definately good for Photopolymers as far as speed and good screens… again, not as good as MH, but very good alternative. Dual cure and Hybrid Dual cure are the best results. The diazo dual cures were excellent. As long as a customer can live with the exposure times, it’s a good unit. The Hybrids were nice and fast, yet had very good imaging.”

I hope this information is helpful as you begin to see this unit in the field. I would not hesitate to recommend this as the best LED screen printing exposure unit to date!!!!!!!!!

Download the PDF to read the results and their analysis for yourself.

Lightspeed Equipment will be at the (Specialty Printing & Imaging Technology) SGIA Expo in Las Vegas, October 22-24th.

We will be at booth #3289, come by and say hi! We will have a demo unit on hand and would love to talk with you about LED Exposure Units and how our latest technology can help you and your business.

See you in Vegas baby, yeah!