Lightspeed screen exposure units advantages

In the video Shawn explains some unique and distinct advantages over other tech and how Lightspeed UV LED bulbs insure a level of detail and quality of shooting screens.

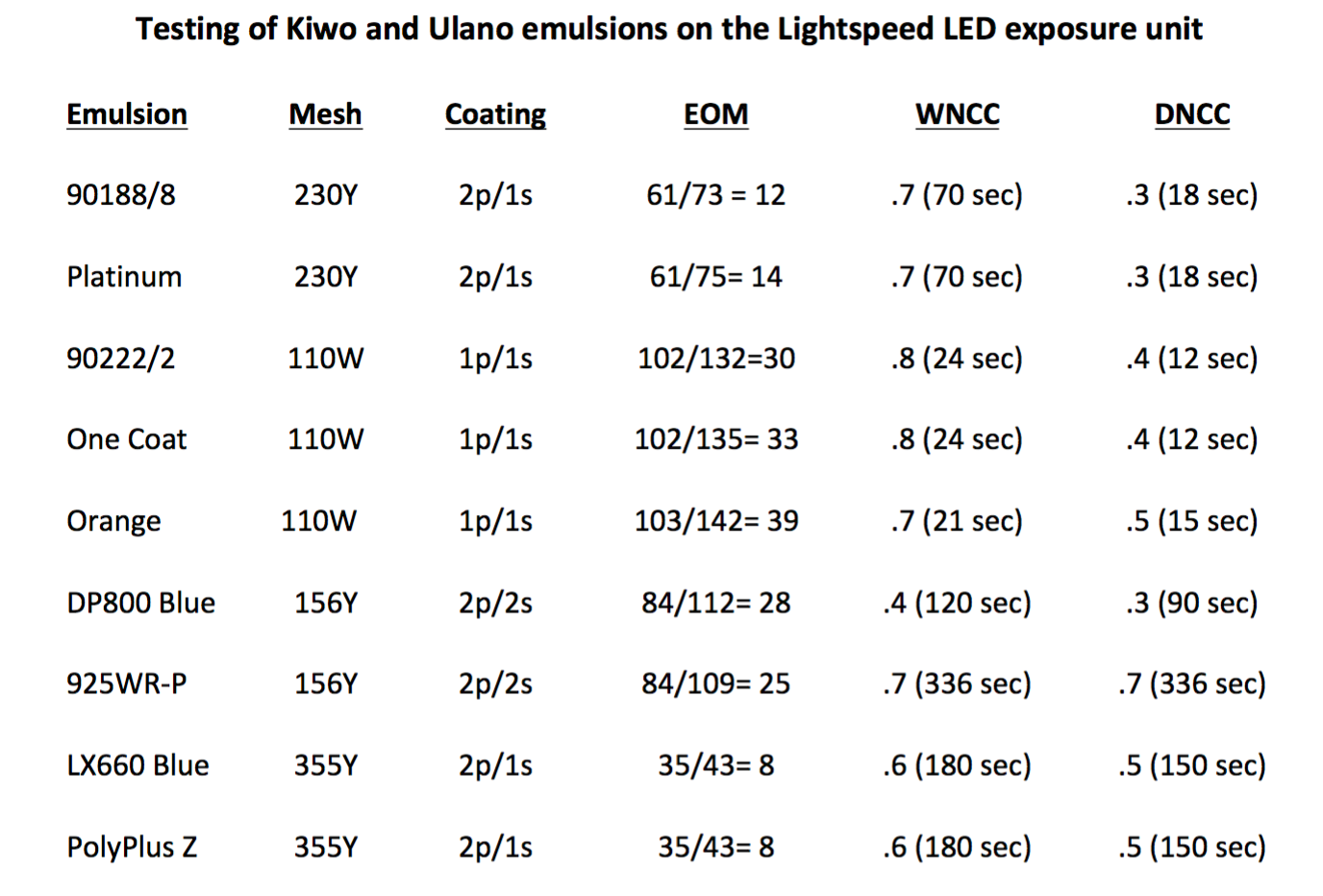

We were the first in development using LEDs in screen printing exposure units, first to put a multi-spectrum led based unit on the market, and what we found during our stages of work on it, and trying to make this work was, a single colored LED would not properly expose all different emulsions. We had to widen that spectrum by at least 2 LEDs of different nanometers per bulb.

So, once we accomplished that feat, patented it, and 2 other people have tried to put 2 colors (LED) in theirs but with the patents we were able to stop them. Lightspeed has the only LED exposure unit on the market that will properly expose. It’s the only unit on the market that has an LED bulbs that’s made specifically for exposing screens. Everybody else is either using black light lighting lights, or rope lights like you might find in a casino, or string lights.

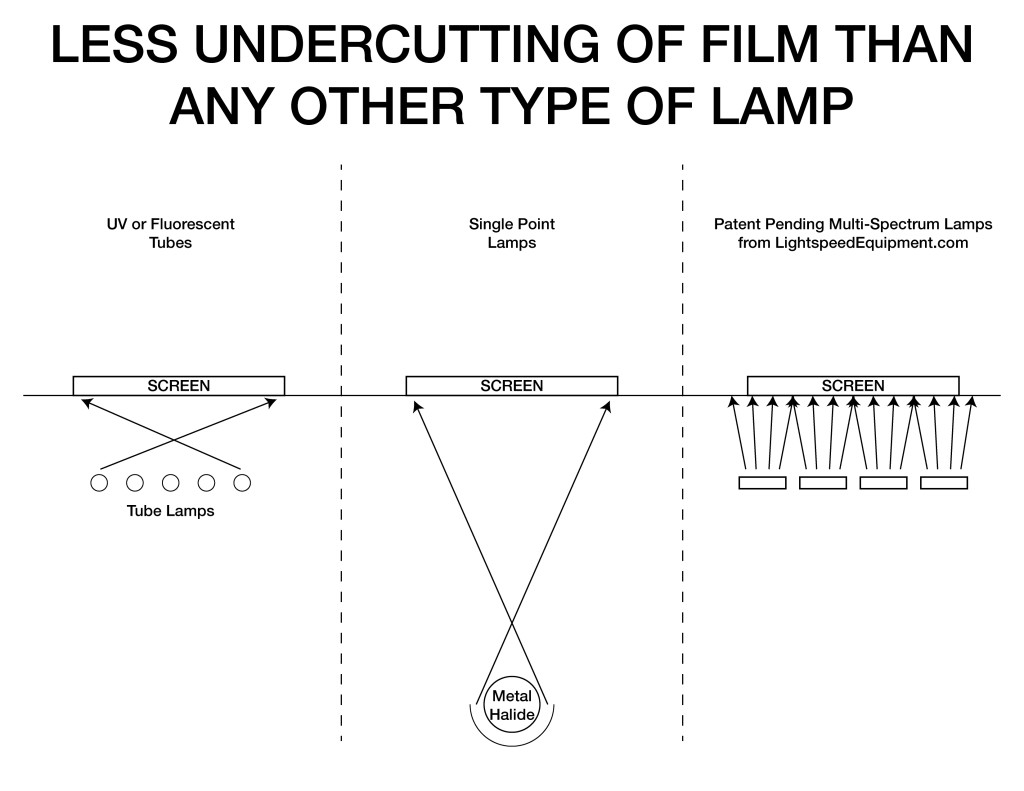

We also developed patented lenses that focus the lumens into a 60 degree angle, to insure crisp, detail screens. No other manufacturer has this feature in their exposure units. You can see the difference in the results when you shoot screens, no matter what kind of emulsion you are using.

Looking for a high quality exposure units for both big and small screen printing projects? Lightspeed exposure units are made in the US, with high-quality parts and the only patented multi-spectrum LEDs bulbs on the market. Literally light years ahead of the competition. Shoot crisp, high quality and professional screens in a reliable, energy efficient unit.

Looking for a high quality exposure units for both big and small screen printing projects? Lightspeed exposure units are made in the US, with high-quality parts and the only patented multi-spectrum LEDs bulbs on the market. Literally light years ahead of the competition. Shoot crisp, high quality and professional screens in a reliable, energy efficient unit.

Exposure units are available in a variety of sized and can accommodate small, medium and large size screen frames. The bulbs are the latest technology and are warrantied for 5 years. Comes with all the standard features you would expect, adjustable exposure times, auto shut off, instant draw vacuum, neoprene rubber blanket, and gas shock assisted frame.

They are energy efficient, low heat, incredibly reliable, and made in the USA.

Learn more at LED UV Exposure Units